This is the size of the mortise. Hopefully some other people will offer their thoughts. in diameter; it is cut on the cross at an angle of about 45 degrees, in cakes of an inch thick, and then slipped in thin pieces and let into the planes so that the working edge is half on the end way of the wood; it is afterwards glued in and allowed to dry for a day or two. You should get years of enjoyment from them. Done with the sewing machine cabinet swap, Sizing up Hollow & Rounds moulding planes. from the square of the ovolo line down, and take the short end of the springing square and strike a line F G from the point measure right across, which gives the stop fence line; then measure with the compasses from the point where the fence line meets the stop line 5/8 in. from the springing line down, bring the short end of the springing square to the measured point, and strike a line C D. This gives the depth of fence, and is the line of the square of the ovolo down. Let's see Krenovian bench planes, hollows and rounds, and now moulding planes.

18. As you can see Ive only worked out for one, but how do you work it out for each plane?

As an example a Hollow or Round plane Stamped No 6 could be. The total cost of materials was $144 to make 17 moulding planes and 2 snipes bills. Save my name, email, and website in this browser for the next time I comment. Then with the springing square mark the lines from the points made from the other tracing. Matt showed me how to make an ogee which was the first time I've really used a hollow and round and even though it didn't turn out perfectly, it was addicting. in thickness, and all are fully boxed. I found a tool, with markings John Moseley & sons with the London address, also marked JT OSBORNE PRODUCTS, also says RT JONES on it,solid wood, looks like its for making moldings or something, can I send a photo & get you thoughts ? Larry's video is excellent.

In fact that is probably 75% of the work. He knows way more than I do about antique planes. I looked up the two DVD's you recommended, and noticed that Larry Williams also has a DVD called "Sharpening Profiled Hand Tools" (92 minutes). to 3/8 in. ; )Travis/GG, I forgot to mention that the line on the toe is called the spring angle. Jeff reckons on around $8 apiece for making a moulding plane and about 5 hours to make them himself, instead of $200+ to buy them new.

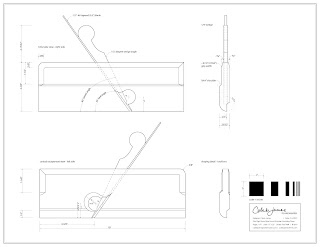

If this is done well it will be hard to see the join; the object of slipping is to enable the plane to work close up to a moulding. Home / Resources: Choosing, Refurbishing & Using Moulding Planes with Bill Anderson. The act of planing causes backward force on the iron. Anyway, here are my drawings for the no.15, they are in A3 and in inches. For instance, he marks all of his layout lines on the beech blank and cuts half of them off only to redraw them. This actually isn't a difficult fix with a little sandpaper and a dowel or "fid" that matches the profile of the sole. document.write(new Date().getFullYear()); Fig. Cod Plane (Full Round Moulder). It should be perpendicular to the face of your board in order to cut the right profile. I look to make sure the sole is co-planar in front of and behind the blade. The same method is applied to common O.G.s; should the moulding be wanted flatter or deeper, the distance on or down must be varied accordingly. 5, p. 8. to 7/8 in. 13. Can you share this document or at least point me in the right direction on where to get it? If users make purchases in those stores (e.g.

Very nicely done. So I turned to autocad and started drawing away, but before I could draw anything, I needed good reference photos of what 18th century moulding planes look like, and tweak them to suit my build. of No 16s or equivalent. larger than the size wanted and cut out with a saw, planed, cleaned, and put back. Caleb isnt going out of his way to produce many planes for sales for the obvious reason that most of us cannot afford them so why bother directing effort into a product that produces no income. Backing Plane: Also called a mother plane. 461) level the bed, and then stick the moulding. Mine are 50, but 55 and 60, also in a smoother, sounds like a good idea. It must be an important escapement. How on earth do you accomplish so much amazing woodwork "on the side"? Beautiful work as usual, Kari.  wider than the rebate; for instance, in a moulding plane 1 3/4 in. Easy enough to be fooled, especially if they are both stamped No 16 and both Mathieson & son. Would love your thoughts, please comment. Hand planes, Stanley planes, infill planes & planemaking. As I said before, he also marks his layout lines on his stock and then planes half of them off just to then redo them, which seems like a waste of time in my opinion. Lovely planes Kari. Well it was back to the drawing board and instead of just sketching it on a piece of paper, I needed something that a little more accurate and permanent.

wider than the rebate; for instance, in a moulding plane 1 3/4 in. Easy enough to be fooled, especially if they are both stamped No 16 and both Mathieson & son. Would love your thoughts, please comment. Hand planes, Stanley planes, infill planes & planemaking. As I said before, he also marks his layout lines on his stock and then planes half of them off just to then redo them, which seems like a waste of time in my opinion. Lovely planes Kari. Well it was back to the drawing board and instead of just sketching it on a piece of paper, I needed something that a little more accurate and permanent.

About using cherry, I had the same concerns as you, but he said he's used the planes he brought to the show to make all the planes he's sold, and I thought they looked pretty much new, and also beautiful but then I really like cherry. Irreparable planes are a good supply of old beech.Often, the soles of these old planes will be slightly warped or not coplaner as you mention above. The blacksmithing isnt that difficult either because you are working with relatively small parts. I was wondering if we could get/purchase your plans for your snipe bills?

To make the half set of hollows and rounds, they should all be cut from one piece of wood, which should be as free from knots as possible.

But wait! It does however behave when sanded. The way to make a plane to an architects drawing, as for instance Fig. Seasoning it for years is a wise idea. :). They do work apparently well though. Excellent post Kari! Can vintage moulding planes be reclaimed the way bench planes can? Ive read quite a bit about the techniques involved in making your own hollows and rounds, but Jeff makes it sound very easy. by 2 1/4 in. I'm tempted to try a rabbet at 55 or maybe 60. With the gauge set to 9/16 in., mark both ends and sole; then take the springing square, fix the spring required, and strike the line A C (see Fig.

Beauties, Kari! You'll want to orient the grain so it's running downhill on the sole and also consider any defects in the wood. 13 and 14) are the most used moulding planes. size, the usual way is to have the wood 1/4 in. 19, 20, 21, and 22. Subscribe to get Joshua's free traditional woodworking videos, articles & news: 2013 - 2021 Wood and Shop Productions & Joshua T. Farnsworth | All content on WoodAndShop.com is copyrighted and may not be reprinted or used without our written consent. I have used curly maple for a couple of planes I've made, and it has held up well. If I can't answer them, I'll bug Bob again.

:) I have Larry Williams' how to video and hope to put the knowledge to use someday soon.Pete.

its full circle being 2-1/2 in Dia. Fig. If it's pitted, I wouldn't buy it. Using moulding planes is definitely addictive! I've been waiting for this post as I was following your class progress on Twitter. Next to hollows and rounds, bead planes (Figs. Saddle Template for Ovolo Sash bar. I started out to make maybe 3 sets of hollows and rounds, but ended up making a half set minus the #4 hollow of John Moseley and 2 snipes bill boxed with osage orange. Steps 1-5 | Beginners Guide to Hand Tool Woodworking, Step 1: Understand & Buy the Right Woodworking Hand Tools, Step 2: Setup your Woodworking Workshop & Tool Storage, Step 3: Learn how to Refurbish, Tune & Sharpen Hand Tools, Step 4: Learn How to Use Woodworking Hand Tools, Step 5: Learn How to Design Furniture for Woodworking Projects, Steps 6-10 | Beginners Guide to Hand Tool Woodworking, Step 6: Learn How to Choose Stable, Strong & Beautiful Wood, Step 7: How to Make Wood Square, Flat, Straight & Smooth, Step 8: JOINERY: LEARN HOW TO LAYOUT & CUT JOINTS, Step 9: Learn How to Assemble, Fasten & Glue-up Woodworking Projects, Step 10: Learn How to Finish Woodworking Projects, Resources: Choosing, Refurbishing & Using Moulding Planes with Bill Anderson, Grinding and Shaping Moulding Plane Irons, Make aWooden Molding Plane with Bill Anderson, How to Choose Wood Lumber for Woodworking | 7 Easy Steps, How to Square, Flatten, and Dimension Rough Boards with Hand Tools, How to Make a Mortise and Tenon Joint with Woodworking Hand Tools, Privacy Policy, Rules, Terms & Conditions. Feel free to ask more questions anytime. I love the soundtrack!All the best,Doug. So I stayed with the quarter sawn solid beech that has been the tried and true method for a couple of centuries or so. I have molding planes, hollows and rounds, that I can use for reference and to shape the soles of the planes.

The foregoing instructions apply to all kinds of moulding planes, the only difficulty is in setting out the different mouldings; the method of doing this will be explained further on. There'll be no end of custom mouldings on your work now! https://www.youtube.com/channel/UCkcdse9tlPmtppQTMyVAmgg, https://www.tiktok.com/@thelostscrollsofhandwork?lang=en, Work a new magazine for the hand toolwoodworker. In addition to the two I own, I've seen the whole range at a show. 15), (see Note 2). in width, and they are all 9 1/2 in. Most workshops operate around $40 p/h plus cost of materials and other general expenses. They were and remains, rather expensive to buy anyway (36 planes), so why buy sizes you are not likely to use! The video is almost as fun to watch as it is to plane! (The pics below show the progress of a pair of side snipes.) There is really nothing more enjoyable (to me at least) than seeing a beautiful molding emerge from a straight stick while using these planes.Since you asked, I'll add a few thoughts.

Pattern of Pitch Board for all Common and Flat planes. Round No 12. Blade width is length of radius, and cut a 60 degrees arc of the circle. Thanks for your post on making a pair of snipe bill planes. Below you will find free resources that accompanythe video Choosing, Refurbishing & Using Moulding Planes with Bill Anderson. You can purchase the DVD or Digital Download right here. Making the blades is what scares me about this.

in diameter. If you don't have Tod's or Larry's dvds, I highly recommend them. What this means is that the iron can be fixed in the plane with less wedging pressure, causing less stress on the wedge and plane body. I have seen some that are way out of whack. I just watched Todd's video about a month ago and have the itch to make a molding plane. Moseley planes are also a favourite of mine. to the square of the moulding (see Fig. I've also thought about checking with some of the local tree services to see if they ever cut any beeches. I enjoyed watching the video.But I wanted to use the post to ask a question. Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. (LogOut/ No tool maker goes out of his way to rip anyone off they charge accordingly much like we all do, only massive corporations will rip people off. and strike the mouth line; from the bed line strike on both sides of the wood the pitch of the bed. Todds video does have some good information about making the irons, from shaping to the hardening and tempering process. Always stick the hollow first and square with the back; see that it does not wind, then stick the round to it; then let in the iron and pare away to the thickness of iron for mouth, and clean and finish the mortise for the wedge, which must next be let in. Hollows, rounds, and rebate planes, however, are excepted; these should be as straight as possible, because the rebate plane, owing to its being cut through, is liable to cast if it is not straight-grained; and most of the hollows and rounds being very thin, are liable to cast if not of straight, mild, and well-seasoned wood. Just came across it. But I dont have the balls to make the walls that thin, instead Im going to make it 1/8 thick which will make the wedges thickness to be 9/32, which is the same width as the tang. Pattern of Pitch Board for Cabinet-makers Moulding Planes. Dang! This is on my list to get a half set of hollow and rounds among with a post and beam drill press and my shop will be 100% unplugged exept for my lights and tv for watching woodworking DVDs. One of these days I'll have to pick one up (i.e., purchase one).Love the vertical line on the end: never seen it before, it it's a tres clever idea.--GG. The best beads have two slips, the second one to bear the work of the fence. Using rounded, various-width grinding wheels works great, but you can shape the blades with files and stones, instead. Your email address will not be published. Then with a saw cut in the mouth along the bed and front line down to the springing line on the sole and through the side just to the handhold; with a small chisel push with the hand and knock the core out, and with a thin chisel sink down to a level with the springing line and the back line of mortise; then bore from the centre of the mortise to the centre of the mouth, and take a small saw float and open the mortise; pare the bed clean, and with a square float (see Fig.

They are very well-made 19thc planes with sharp boxing and a nice wedges. Next, with a rebate plane, rebate out the angles at F, G, H, and K (see Fig. Those that are in the high salary brackets not the tradesman he cant afford them so he makes his own but the hobbyists they are the ones who can and will pay top dollar. If I bought a log and rived it into billets, in four or five years I'd have quartersawn beech coming out of my ears! and about 3/16 in. The handholds are 3/4" thick and thickness of the rest of the bodythe part with the soleis determined by the width of the profile. So I turned tohttp://msbickford.com/and clicked on his hollows and rounds. Backing Plane (Mother Plane) for Ovolo Sash Saddle template. What is that book with the planes in it a old tool catolog? Then measure with the compasses a full 1/8 in. Do any of you know how to work out what the wedges thickness should be for each plane and what the top half of the body of the planes thickness should be for each plane. I can understand where the costs are coming from, you mentioned the timber costs around a $8 piece but the real costs lie in labour. 12. I dont recommend anyone use osage for boxing because it is really gnarly, but it did succumb to sandpaper. How much would be reasonable to pay for a vintage molding plane? I have a pair of his snipes bills, and they are great tools. What types of problems should I anticipate anticipate? Good luck making your plane! As per the table shown previously they would be No 9, 18 or 20, They are both stamped 16 but one has a blade 1-1/4 the other 1-3/8 wide. Make sure the wedge isn't broken or if it is, that you can make a replacement. Beads are mostly slipped on the side to the 1/2-in. The scale boards required in setting out moulding planes are illustrated in Figs. Minor chips or crack are ok if you are comfortable reparing them. You can see that this scrap piece of lumber was previously used as a backer board for drilling through holes and probably a couple of other things. (LogOut/ 17); in the former instance the size of wood would be 2 in. A 1-1/4 in blade can cut a circle twice its size (twice its radius). Wedge thickness is not standardized but 18th c. molding planes had more graduated wedges than did 19thc ones, which tended to use only a few standard thicknesses. He talked about laminating and I remember Larry saying not to do that, but I can't remember why. Have you been able to source 12/4 qsawn beech for those wider planes? Cheers Peter. gchpaco, we did use quartersawn, non-laminated beech, but I'm not sure where Tod got it.

Hi ToddSorry for the late reply, just saw your commentsYes, the book is called Wooden planes in 18 century America (part of a 2 books set)By Kenneth D Roberts and yes, that is a tool catalog on top of it, Sandusky Tools Co.You can see more about these in a previous post of mine, back on 14 Oct 2015; About wooden planes restorations, Step 1 identificationCheers Bob, Molding or Moulding planes? Most other problems can be repaired with a little patience. As others have pointed out, finding the beech is difficult, so I'll probably use cherry and maple for now. After this is done, measure from the fore end on the sole 3 1/2 in. However, what do you do when you need a blank that fits a 2 3/8 cutter and all that you can get is 8/4 rough qsawn beech that 2(ish)? Fig. With that I mean something I can refer to every time I make a new plane, and I will be making a lot of them.

Looks like the planes work great too. Thank you Kari for the dimensions, and thanks Bob for the great information you added to the post. They go down in increments, but by how much? Any product claim about a service or product should be verified with the manufacturer.

Dean, here are dimensions for less complex moulding planes, including hollows and rounds. While the planes will work with a parallel iron, a tapered iron is an improvement. Kari,Fantastic job on the planes! All beads have a slip of Turkey box let in to bear the hard work of the quirk. 16. In one of your pictures, there is a blueprint of the snipes bill plane that you are making. This plane is the reverse shape of the desired moulding and is used to cut the profile on a plane blank more quickly and consistently. The method of letting in the slip is to plough down with an ordinary plough to the depth of 1 in. This is only one plane, I still the rest to draw and I wonder if the top half goes down in increments of 1/4 or less. The pic below shows Jeffs plane (top) with one of his vintage Moseleys below. The hardest thing to make on the moulding plane is the tapered mortise and that isnt all that difficult. I'll tap on Bob Razeiski's shoulder to see if he'll add to this thread. But if you're going to make a coffin smoother or large plane, it might be different. I will probably use maple if I can't find quartersawn beech.Thanks, Doug and Jack! I cut out the blanks and tapered them with the angle grinder and then used files to finish them.

I could put a mirror at the end of the bench and use such reference lines to get square edges.And like Tico, I wonder how you get so much done. Something about blocking moisture. If you do get ahold of a nice big beech log, don't forget about your buddies! They are seldom used by other mechanics. Thanks Steve I actually do have one I bought years ago from LN. But yes, a shelf seems more practical. I used this because I just happened some and thought that it would make a good boxing material. Forgot I had it thanks for the tip and reminder. Matt's planes are great. ; )Bob, using a mirror--what a great idea! Because the tangs are 1/4" wide and the handholds are 3/4" thick, the walls inside the mortise are 1/4" thick.I *think* planes made in the 18th-century are the longer ones9.5". The plane Im currently working on is a no.15 which means it has a radius of 1 1/8, just what is supposed to be the thickness of that wedge, I dont have the faintest. I can foresee a trip to the Woodwright's School in Tarboro, NC to make a period toolchest to house them in. Plane the wedge so that the pressure goes to the bottom of the mortise, and when driven home it will slightly spring on top; afterwards shoot the ends and trim.

Those would make good videos. Out of interest Salko, have you come across Dutch style moulding planes ? The latter is called half pitch. and strike the bed line; from this line measure 3/16 in. Great looking planes Kari. I spoke to a tool maker and asked him who is your biggest clients and he was honest when he answered the hobbyists who are bankers, accountants etc. The method of setting out these two planes will now be described, and the sizes, taken by way of example, will be 5/8 in. If not, you should get it, it will answer most of your questions. Does this pose any problems?Jamie Bacon. ebay.com and Amazon.com) those affiliate links may lead to referral compensation to us. You can definitely make these planes. along the stop line, and take the springing square to the point measure and strike a line HK; this is the line of the square of the ovolo. I like your video, too. Thanks. Planes made in the 19th-century in the U.S. are shortermore like 9". Traditionally it's done with quartersawn beech but that's really, really hard to find in 16/4.

Bob, thanks so much for offering your advice!Dean, yes, you have it right regarding the blank. Assuming that the size of the moulding measures 1 3/4 in., the size of the wood would be 2 7/8 in., to allow for the stop fence and springing measure from the back.

:DVittorio, thank you! About the sharpness levels required on moulding pl About wooden plane restoration Part 3 Fine tuning. 11. You will have a beautiful set of planes with that wood. 23, will now be explained. NOTES: Thanks for sharing. These photos served as a base reference point, theres no measurements I could work from but judging by eye, I know that the smallest 1/8 planes wedge must be about 1/4 thick and the thickest to be about 3/8 and I have a plane that has a 1/2 thick wedge. One person's woodworking journey, with a focus on handtools, a nod to the past, and an appreciation for the creative spirit.

If you dont mind Id like to ask for your advice when I get to the point of making a couple snipe bill planes. Regarding the tapered iron, I actually agree with Larry Williams on this.

With these thin moulding planes, I bet it's not as much of a problem to laminate pieces. Don't forget to tick what you already have with a H or a R.Sylvain. They have slightly bigger blade width. Not a common terminology. Common O. G. Scale I realised with each planes different width, the wedges thickness will also be different. long; the mouldings of all are parts of circles varying from 1/4 in. I am planning on making a few side beads and a set of side rounds.

Then take the springing square S, and place the fence F of the square firmly to the back of the plane, as shown in Fig. I think that C&W tapers their blades so they always bed correctly. 24); then draw line B C from the point C; this is the fence line. The three on the right have been culled from the pile on the left (5). I've had good luck with ebay, but I've bought some worthless examples from there as well. The snipes bills have persimmon "boxing," which is what Clark and Williams use. However, with the tapered iron, the taper resists the force of planing. We run our website based on principles of integrity, and dont recommend any product that we wouldnt use ourselves. It isnt as difficult as one might imagine to make a moulding plane. Bluing of the iron is of no consequence at this point in the process, that can all be taken out when it is hand filed to the final shape.

16) and 1/2 in. I have a number of irons that I got off of eBay, but Im not reluctant to make my own irons, which I did during the construction of the half set of moulding planes. Fig. Keep them toward the top of the plane, in the handhold, and try to place them so they can be trimmed off. Pete, I'll really look forward to talking with Matt at WIA and getting an up close look at his planes. Quartersawn beech is hard to get rift sawn is easier but both are also very expensive so Tod Herrli is right in what he does, laminating really is the most cost effective way of doing it. wide the rebate taken out would be 3/4 in.

I got a supply of irons and set of floats back in the fall at an LN tool event, so I'm all set to follow Larry Williams' DVD to fill out my random collection of antique hollows and rounds. No.

They will probably wonder what is a hollow and round. and could be stamped No 9, No 16, No 180 and etc. I dont think so but these guys are crucial to us the users because once theyre gone they will sell for double in antique shops, eBay and tool dealers. Thanks, Dean. I appreciate your willingness to share information here. I've never used a moulding plane, and don't know much about them. Fig. Granted, its only for a few of the largest planes but its gonna happen.

The moulding planes were really neat to make especially since I made 11 of the irons from scratch using an angle grinder. Matt Bickford, another new planemaker, uses quartersawn cherry.