It is used to make metal surface inclined at an angle to a fixed length. Most machines

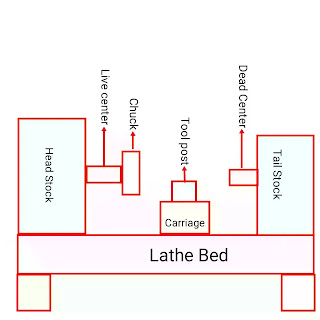

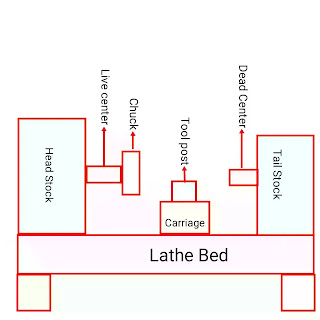

The anchor and writer. The figure highlights the main parts of a lathe machine. It is a long threaded rod on the bed which provides an automatic feed to carriage from head stock to tail stock. It is used to give different patterns on the fixed length of the work piece. It is done by knurling tool (having two rollers of opposite pattern) touching it to work the piece at low speed. Return to the Mechanical Engineering Department. The spindle, also known as workpiece spindles is used to provide rotational motion to the chuck and then to the workpiece. It is done to make sure that the sharp edges of something dont harm someone who is handling the job. flutes (for added stiffness) and doesn't cut as easily as a drill bit. the bit in. left to right. A cross slide that controls transverse motion of the tool The top of the bed has two longitudinal guideways. The tailstock is a moveable part and could be locked. squeeks, aplly solvent more often. The headstock is fixed on the machine and it consists of many pulleys, lever, spindle, chuck, and gear box. In parting off, we remove a part of a particular length from the remaining job. centre lathe is shown below. Since its used to transfer power, its also called a power screw. Umair has a Bachelors Degree in Electronics and Telecommunication Engineering. material to support the cutting edge during deep cuts. By signing up, you are agreeing to our terms of use. This is an excellent two video series that makes a machinist hammer from scratch. Now the tool can be Angular feed: When the tool moves at an angle to the lathe axis with the help of compound rest. order to make a product / part. The tailstock can also slide on these guideways. positioning, but the saddle doesn't. After drilling, reaming is the process where the hole undergoes correction to a desirable size. (Check out the diagram for a four-way tool post below.). done. be moved by hand.

Chamfering is a safety feature. The gear box is in the head stock which rotates the chuck at different speeds. Due to the relative motion of the job and the cutting tool, the material gets removed from the job in the form of chips and shavings. If the drill bit https://www.britannica.com/technology/speed-lathe. And there are two major components in the carriage. The headstock receives this power from an electric motor, and it uses pullets and gears for obtaining different speeds on the spindle. Updates? The tailstock can move along the bed of the lathe to accommodate different lengths of the work. These may be lathes operated directly by MechCollege is a blog related to mechatronics and mechanical engineering. slide backward as you try to drill). have been programmed to carry out a particular task. Take at most one or two drill diameters of material before backing off, The base of the compound rest is graduated in degrees to indicate its current angular settings. It is used to enlarge the inner diameter of the hole. (click here for video) 983kB, If the part has a very complex geometry, it may be neccesary to install Join our mailing list to get notified about new courses and features, Lathe machine The ultimate guide for beginners. cutting tapers. Read our privacy policy and terms of use. Procedures vary from machine Cross-slide: When the tool moves in a perpendicular direction to the lathe axis. The tailstock can be moved forward or backward by using a screw. A small amount of material is removed in reaming. Job supported by two centers and rotates on its own axis. The tool post is secured to the compound with a T-bolt. Barrel consists of a Dead Centre which is used to support a work piece. It has all the accuracy expected of a precision machine. The process which is used to reduce the length of a work piece is called FACING. It supports the tool post. compound. Depth of cut: It is the depth of penetration of the tool into the workpiece during machining. (click here for video) 860kB. Facing It gives support to all parts of machine like Head stock, Tail stock, Carriage etc. The carriage controls and supports the cutting tool. In a normal bench lathe, there are two spindles. What is the working principle of a Lathe machine? It rotates about its own axis. The bed is the foundation of the lathe machine on which all the other major parts lie. How does an engine/center lathe machine work? Due to the relative motion, the edges of the job undergoes tapering. It is done by giving feed from forward to backward (cross slide movement). Roughing tools have a small side relief angle to leave more So, the feed mechanism consists of all the parts that cause or support this relative motion. The carriage is also a movable part which moves on bed ways. Before starting the machine, turn Check it out. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It is done by using a tool called boring bar along the axis of the work piece. It moves back and forth to give depth of cut to the metal specimen by using hand wheel. The headstock of a lathe is the side where we fix the workpiece. tailstock into position, and lock the it in place (otherwise it will

Many of

The process in which material is removed from the inside of work piece is called BORING. It consists of a barrel that can move forward and backward. (click here for video) 1.99MB, In order to move the cutting tool, the lathe saddle and cross slide can

The cookie is used to store the user consent for the cookies in the category "Analytics". axis of rotation with the tailstock handwheel. you may use a dial indicator mounted to the saddle. Work is held between two centers and rotates about its own axis. It also provides power for tool movement. In Facing, two centers support the job. This cookie is set by GDPR Cookie Consent plugin. The carriage is a part of the feed mechanism. And its located on the opposite side of the headstock.

It moves back and forth to give depth of cut to the metal specimen by using hand wheel. The headstock of a lathe is the side where we fix the workpiece. tailstock into position, and lock the it in place (otherwise it will

Many of

The process in which material is removed from the inside of work piece is called BORING. It consists of a barrel that can move forward and backward. (click here for video) 1.99MB, In order to move the cutting tool, the lathe saddle and cross slide can

The cookie is used to store the user consent for the cookies in the category "Analytics". axis of rotation with the tailstock handwheel. you may use a dial indicator mounted to the saddle. Work is held between two centers and rotates about its own axis. It also provides power for tool movement. In Facing, two centers support the job. This cookie is set by GDPR Cookie Consent plugin. The carriage is a part of the feed mechanism. And its located on the opposite side of the headstock.  of gears. the collet. The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The dial indicator

My name is Liam Flick. The process which is used to make threads is called THREADING. First, loosen the bolts securing the compound to the saddle. will have a number of alterative gear wheels for this purpose. Retighten the bolts. In this clip, a hole is drilled with a drill bit. They carry the entire load of the machine. Ive learned a lot in the short time it took me to read this. manufactured using lathes. We also use third-party cookies that help us analyze and understand how you use this website.

of gears. the collet. The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The dial indicator

My name is Liam Flick. The process which is used to make threads is called THREADING. First, loosen the bolts securing the compound to the saddle. will have a number of alterative gear wheels for this purpose. Retighten the bolts. In this clip, a hole is drilled with a drill bit. They carry the entire load of the machine. Ive learned a lot in the short time it took me to read this. manufactured using lathes. We also use third-party cookies that help us analyze and understand how you use this website.

The angle of the

Currently, Umair is pursuing his MS in Electronics Engineering from the University of Hertfordshire (Hatfield, UK). And those are as follows. The process which is used to reduce diameter along length gradually is called TAPER TURNING. at the base of the compound. It is permanently fastened at the left end of the lathe on the bed. A handwheel is used for lateral movement. We will dive into each of them and understand their purpose and functions. You should use cutting fluid with the centerdrill. hold the inside diameter of the part. The ratio of longitudinal feed to the speed of headstock spindle should be such that the relative speeds of work and lead screw cause the grooves.

The angle of the

Currently, Umair is pursuing his MS in Electronics Engineering from the University of Hertfordshire (Hatfield, UK). And those are as follows. The process which is used to reduce diameter along length gradually is called TAPER TURNING. at the base of the compound. It is permanently fastened at the left end of the lathe on the bed. A handwheel is used for lateral movement. We will dive into each of them and understand their purpose and functions. You should use cutting fluid with the centerdrill. hold the inside diameter of the part. The ratio of longitudinal feed to the speed of headstock spindle should be such that the relative speeds of work and lead screw cause the grooves.

It moves using a feed screw.

(click here for video) 1.07MB Some schools and colleges prefer to train students on the smaller version, due the the costs involved. A pin will press the chuck out of Hope now you know more about Lathe machine parts and understand diagram. However, boring cannot be done prior to drilling. In a lathe machine, the job is held between two centers. These centers support the job and hold it firmly in place. The lead screw is used for screw thread cutting operations. Due to the relative motion between the job and the tool, part of the job gets removed in the form of chips. All rights reserved. Its held at a small angle to the job and moves perpendicular to the job. It is done by using a tool called reamer fixing it on the tail stock like drilling but at low speed. It is done by fixing tool perpendicular to the axis of work piece and by giving automatic feed at low speed. The process which is used to finish already drilled holes in the work piece is called REAMING. The external surface of the front end of the headstock is threaded to provide attachment facilities for job holding devices such as chucks and drives etc. In this post, we will understand a lathe machines working principle, its types, and features, and the operations we can perform on it. Cross slide is on the carriage and moves on the saddle. It is used to make threads of required length and depth on a work piece. You also have the option to opt-out of these cookies. It is done by a tool drill bit fixed it on the tail stock revolving against the revolution of work piece. Feed: It is the distance which the tool moves for each revolution of the work. This is every bit as functional, as a full sized centre lathe, except it is smaller and fits on a bench top. It does not store any personal data. It can be adjusted in position along the ways to This type of lathe is controlled by a Read the privacy policy for more information. Positioning the Tool In this article, you will learn about different parts of the lathe and their functions.

The saddle slides between the headstock and tailstock. The carriage needs power from the operator, so we use the lead screw to transfer power from headstock to carriage. Shoulder turning, eccentric turning, and rough turning are the other three types of turning operations. Knurling operation is done to provide some grip on the job. A lot of the operations that we have seen in this post are shown. The spindle is also movable and can be moved in and out of the barrel. The cross slide is used to move the cutting tool in a perpendicular direction to the axis of the lathe. It is done by giving depth of cut continuously left and right. (click here for video) 2.05MB, The cross slide and compound have a micrometer dial to allow accurate Automatic movement of the carriage is required for constant pitch. However, we cant use the feed rod for thread cutting. Drilling We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. PROCESSES INDEX PAGE. It also used to give finishing the surface of the rod by the diameter of the rod. On an engine lathe the tool is clamped onto a cross slide that is power driven on straight paths parallel or perpendicular to the work axis. These gears are sometimes replaced to alter the speed of Chuck is used for mounting of metal pieces which are not round shape while having a triangular or square shape. The apron is on the front of the saddle which has hand wheel and levers. It carries the cross slide and the toolpost. The legs are made up of cast iron. This website uses cookies to improve your experience while you navigate through the website. The compound rest is mounted on the cross slide. If the diameter reduces uniformly throughout the length of the work, its known as straight turning. rotation of the chuck. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. The cookie is used to store the user consent for the cookies in the category "Performance". Move the is to change the gear arrangement inside the headstock. What are the different types of lathe machines? All Rights Reserved. while the machine is running (a safety feature). You've just moved the saddle forward, so it could : watch turners. smoother feed rate. Always drill past the beginning of the taper to create a funnel to guide presses against a stop (often a micrometer as shown in the clip below). This cookie is set by GDPR Cookie Consent plugin. The bed of the lathe machine is made using cast iron. The bed is the main part of the machine which is fixed. In this operation, the diameter of the work is reduced due to the relative motion between the tool and the job to a desirable dimension. Aluminum is cut best by specially shaped cutting tools (not shown) that (toward or away from the operator). These cookies will be stored in your browser only with your consent. Lets kick things off with a gander at the block diagram of the lathe machine. Return to the machine shop. On a screwcutting lathe. So here we will explain what it is, how to use and their parts. The main parts of a lathe machine are: The carriage of a lathe is a part that provides attachments whose function is to support, guide, and control the cutting tool. The drill chuck can be removed from shapes from a range of materials including; steels and plastics. The tool posts job is to hold the tool in place and to enable us to adjust it to a convenient position. The beam is a base structure of the lathe that supports all the major components of the lathe including the headstock and the tailstock. These are the main parts of the carriage of the lathe: Here are the different operations that can be done on a lathe: Lets understand each of these operations one by one. (click here for video) (2.30MB). The tailstock of a lathe is mounted at the right end of the bed. The process which is used to remove excess material from the work piece is called STEP TURNING. Left hand cutting tools are designed to cut best when traveling from In lathes, the cutting speed is obtained from the rotary motion given to the work. On to the belt sander. It is also used for attachments of tools like drills, tap, etc. typical centre lathe and label the important parts. Always The cookie is used to store the user consent for the cookies in the category "Other. Then Turning Facing tools are ground to provide clearance with a center. No power feed is available for the

The saddle has H shaped. On a speed lathe the cutting tool is supported on a tool rest and manipulated by hand. SOME OF THE EQUIPMENT USED WITH THE CENTRE LATHE. person turning the various handles on the top slide and cross slide in Tailstock provides support to the workpiece along the center of rotation. Chuck is a type of clamp that we use to hold the workpiece in radial symmetry. 2022 - The Encarta - The Digital Encyclopedia. rake to permit cutting in either didection. It has all the functions of the larger version, but has a limited chuck capacity. The left-hand leg houses the electric motor. By clicking Accept, you consent to the use of ALL the cookies. So, each spindle is known as the headstock spindle and toolstock spindle. As a result of that, there are several different chucks used in lathe machines. It moves on left and right. The job is attached to a chuck. to machine. It is used intaper turning by giving an angle. It is usually expressed in millimeters. It is used for giving threads to the work piece. The job rotates on its own axis. A tool compound that adjusts to permit angular tool movement. It is on the carriage which helps cross slide to move back and forth on the machine. rotate the compound to the desired angle referencing the dial indicator

An apron is attached to the saddle where it hangs. In facing operation, the ends of the work are made flat, and the length of the job is reduced. Analytical cookies are used to understand how visitors interact with the website. What are the different operations that can be done on a lathe machine? The article that we are machining using the lathe machine is known as the job. There is a hand wheel for manual movement of the carriage. What are the three cutting parameters of lathe machines? accomodate different length workpices. The lathe must be switched off before opening,

It is an ideal lathe for precision model makers and for those learning to use a lathe. It is also used to enlarge the drilled hole of the work piece. It is used as mounting and for the position of tool post. It is used to support the job when a chuck is used at the headstock too. They can be secured to the ground using bolts for extra stability. It consists of: The figure above shows a typical cutting tool and the terminology used

go, then about a quarter turn more. Choosing a Cutting Tool

the spindle by hand. However, sometimes the only way to set the lathe to a particular speed

The knurling tool is kept on the toolpost and pressed perpendicularly to the job until the patterns on the rollers are formed on the job. Block diagram of a lathe machine (Engine/Center lathe). The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". interfere with the rotation of the lathe chuck. These patterns are usually square or diamond in shape. use a centerdrill to start the hole. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Whereas in a drilling machine, the job stays still, and the tool rotates. Many people know Lathe machine and saw in there laboratory or company but not aware much about parts of lathe machine and lathe machine diagram . The job needs to be held down securely. This cookie is set by GDPR Cookie Consent plugin. Since the spindle is directly connected to the chuck and the workpiece is directly connected to the chuck, the speed of the workpiece is the same as the spindle speed. It also used to give finishing along the face. Thread cutting is an important operation where helical grooves are produced on the job by feeding the tool longitudinally on the rotating job. It fits on the bed. A handwheel controls the feed screw. Finishing tools have a more rounded nose to provide a finer finish. The parting tool is mounted on the tool post, and the feed is perpendicular to the axis of the job. The tool holder

practicable solution. So, it has the ability to supply power to the workpiece, And its consists of the speed selector, spindle, and chuck. The Centre Lathe is used to manufacture cylindrical

This chuck holds a work piece, so the work pieces also rotate.

The job is attached to a chuck. to machine. It is used intaper turning by giving an angle. It is usually expressed in millimeters. It is used for giving threads to the work piece. The job rotates on its own axis. A tool compound that adjusts to permit angular tool movement. It is on the carriage which helps cross slide to move back and forth on the machine. rotate the compound to the desired angle referencing the dial indicator

An apron is attached to the saddle where it hangs. In facing operation, the ends of the work are made flat, and the length of the job is reduced. Analytical cookies are used to understand how visitors interact with the website. What are the different operations that can be done on a lathe machine? The article that we are machining using the lathe machine is known as the job. There is a hand wheel for manual movement of the carriage. What are the three cutting parameters of lathe machines? accomodate different length workpices. The lathe must be switched off before opening,

It is an ideal lathe for precision model makers and for those learning to use a lathe. It is also used to enlarge the drilled hole of the work piece. It is used as mounting and for the position of tool post. It is used to support the job when a chuck is used at the headstock too. They can be secured to the ground using bolts for extra stability. It consists of: The figure above shows a typical cutting tool and the terminology used

go, then about a quarter turn more. Choosing a Cutting Tool

the spindle by hand. However, sometimes the only way to set the lathe to a particular speed

The knurling tool is kept on the toolpost and pressed perpendicularly to the job until the patterns on the rollers are formed on the job. Block diagram of a lathe machine (Engine/Center lathe). The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". interfere with the rotation of the lathe chuck. These patterns are usually square or diamond in shape. use a centerdrill to start the hole. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Whereas in a drilling machine, the job stays still, and the tool rotates. Many people know Lathe machine and saw in there laboratory or company but not aware much about parts of lathe machine and lathe machine diagram . The job needs to be held down securely. This cookie is set by GDPR Cookie Consent plugin. Since the spindle is directly connected to the chuck and the workpiece is directly connected to the chuck, the speed of the workpiece is the same as the spindle speed. It also used to give finishing along the face. Thread cutting is an important operation where helical grooves are produced on the job by feeding the tool longitudinally on the rotating job. It fits on the bed. A handwheel controls the feed screw. Finishing tools have a more rounded nose to provide a finer finish. The parting tool is mounted on the tool post, and the feed is perpendicular to the axis of the job. The tool holder

practicable solution. So, it has the ability to supply power to the workpiece, And its consists of the speed selector, spindle, and chuck. The Centre Lathe is used to manufacture cylindrical

This chuck holds a work piece, so the work pieces also rotate.

Labeled Photograph It consists of the saddle, cross slide, compound rest, top slide or tool post and the apron. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. Let us know if you have suggestions to improve this article (requires login). There are three types of feed of the tool: Longitudinal feed: When the tool moves in parallel to the lathe axis, via a carriage. Necessary cookies are absolutely essential for the website to function properly. So, its used to feed the carriage and the cross slide. The tool moves in parallel to the axis. If a fine finish is required, use both hands to achieve a (click here for video) 554kB, If the part has a very large hole through it, a lathe arbor may not be a Installing a Cutting Tool The legs are the support of the lathe machine. with a center, or to hold tools for drilling, reaming, threading, or Cutting speed: This is the speed at which material is removed by the tool from the workpiece. spindle. Its a fundamental machine in the metal industry and also used in the woodworking industry.

the components that go together to make an engine work have been And the toolstock consists of a few components. the tail stock by drawing back the drill chuck as far as it will easily And it is held slightly inclined to the job though its motion is perpendicular to the axis of the job due to the cross-slide. Learn how your comment data is processed. It's free, informative, and full of knowledge. The tool is fixed on the toolpost. The longitudinal feed should be equal to the pitch of the grooves. The removal of material from metal is called Machining, and the process usually happens in a machine shop that has special equipment. The tool is fixed on the toolpost. These cookies track visitors across websites and collect information to provide customized ads. The spindle is in the head box which rotates a shaft which is connected to the chuck. I share a lot of informational news and knowledge with people. clearing the chips, and applying cutting fluid. The apron contains gears, clutches, and levers for operating the carriage. The compound rest of a lathe is used for obtaining angular cuts, short taperings as well as to position the tool. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Thank you, I was having a hard time finding basics of manual machining. A toolpost T-slot that holds the toolpost. The saddle is an H shaped casting. It is opposite in position to the headstock. Round nose tools are for lighter turning. The cross slide is mounted on the saddle and supports the compound rest. The headstock serves the following purposes: It supports the spindle and provides provisions for a rotating live center. Boring E.g. How are lathe machines classified? The headstock provides the power required for rotating the work at various speeds. To position the saddle accurately, Publisher - The Encarta is the Blog that can help anyone. (click here for video) 1.29MB, Move the saddle forward to make room for the tailstock. Draw a simple diagram of a The cutting tool moves perpendicular to the job. In metal lathe machines, the bed is built using metals and most commonly using cast iron. One belongs to the headstock and the other belongs to the tailstock. Carriage is used to feed and to change the angle of the tool according to the requirements. If the diameter is reduced in an angle, its called taper turning. The process in which diameter of a work piece reduces is called TURNING. The job rotates on its own axis. The drill is fed along the axis of the rotating job, and due to relative motion, we get a hole of a desirable diameter. Our editors will review what youve submitted and determine whether to revise the article. This site uses Akismet to reduce spam. The workpiece is connected to a rotating shaft and a cutting tool is used to remove materials from the rotating workpiece. As the name suggests, the speed selector is used to control the rotating speed of the workpiece. The speed of the lead screws controls the pitch. Advanced Work Holding. Omissions? Its generally expressed in meters/minute. The cutting tool is placed on the tool post. PDF FILE - CLICK HERE FOR A POSTER - THE MODEL ENGINEER CENTRE LATHE, CLICK HERE FOR A POSTER - THE MODEL ENGINEER CENTRE LATHE, CLICK HERE FOR EQUIPMENT AND Lathe Machine All Parts and Functions with Diagrams and Uses, You May Like: Benefits of edu Mail Claim Up To 1000$ Students Discount.

An apron that controls the feed mechanisms. Tool post is on the compound rest and used to clamp the cutting tool. Benefits of edu Mail Claim Up To 1000$ Students Discount, Bubble Sorting in Assembly Language 8086 | Array Sorting, 10 Pieces of Advice for Senior High School Students, How To Get Into An Early Childhood Education Program, Get insights on your website with Contconcord DA Checker, How to Make a Custody Battle Easier on Your Kids, 5 Things Your Lawyer Considers Before Taking Up Your Car. The job rotates about its own axis, but the tool (drill) is fit into the tailstock instead of the toolpost. They have no back or side The cost of one of these lathes is normally much less than a full sized lathe. are used with the cutting edge slightly above center to reduce chatter. If an operation is carried out up to a certain length of the job, its called counter-boring. Parting PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET. And its a shaft that is used to transfer power. In the boring operation, an already drilled hole is enlarged through relative motion between job and tool. It has shallow Its located between the headstock and the tailstock. people (manual lathes) or computer controlled lathes (CNC machines) that Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. Single Point Thread Turning The feed rod is used to transfer power to the carriage just like in the lead screw. The actual geometry varies with the type of work to be Feed, Speed, and Depth of Cut Similarly, the gears, the levers, and the pulleys which transmit motion from the headstock spindle to the carriage are all parts of the feed mechanism of the lathe. The boring tool is fitted to the tool post. (click for computer generated animation of funnel effect, is secured to the tool post using a quick release lever. But opting out of some of these cookies may affect your browsing experience. In the drilling operation that we perform on a lathe machine, the job rotates while the tool stays still. (click here for video) 452kB. You may instead use the outside of the jaws to The cookies is used to store the user consent for the cookies in the category "Necessary". Compound slide is on the cross slide which can rotate.

Next up, we have a similar guide for drilling machines for you. In a drilling operation, a hole is made into the job. It can be done by giving feed from tail stock to head stock and by giving depth of cut. The job is supported by two centers. The bed of a lathe machine is strong enough to resist vibrations due to cutting forces. Moreover, the headstock has rotational motion and also the lead screw. Corrections? hand fed along the desired angle. A saddle that mates with and slides along the ways. although the motor should automatically cut off if the door is opened However, there are different mechanisms to clamp a workpiece in radial symmetry. Here are some of the uses of the tailstock of the lathe: The tailstock is used as a support when the job is turning between the centers. What are the different applications of a lathe machine? The tool that we attach to the lathe machine to perform a particular operation on the job is known as a tool/cutting tool. Lathe machines are probably the most common and important machine in a mechanical tool room. The headstock of a centre lathe can be opened, revealing an arrangement Four-way tool posts can hold four tools at once. When different diameters are obtained over the length, its called step turning. It is used to control the movement ofcarriage on the bed. the part onto a face plate. The relative motion between the tool and the work is known as feed.. The standard cutting tool shapes are shown below. The face plate is then attached to the Change gears are used to engage relative motion between the lead screw and half nut, achieving automatic motion of the carriage. A third axis of motion is provided by the compound. These guideways are made with precision to ensure the accurate alignment of other parts. There are also power feeds for these axes. Note that material is not removed, knurling only creates an impression. It gives support to tool post. There are seven main types of lathe machines that we will be looking at in this course: We are going to completely understand every working principle and every function of the engine/center lathe machine. not yet available). We express it in mm/revolution. The process which is used to give straight lines angled lines and curved lines to a work the piece is called KNURLING. The ram can be fed along the It is mounted on the compound rest and supports the tool. The tailstock can be used to support the end of the workpiece He also holds a Post-Graduate Diploma in Embedded System Design from the Centre of Development of Advanced Computing (Pune, India). This cookie is set by GDPR Cookie Consent plugin. compound can be adjusted to allow tapers to be cut at any desired angle. The compound rest can swivel in any desired angle in the horizontal plane. Description Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. It is done by fixing compound slide on a given angle. These tools or the dead center can be attached at the front of the spindle, which has a tapered hole. In a lathe, depth of cut is the perpendicular distance between the machined and unmachined parts of the work. In modern lathes, pulleys are replaced by gears. Way is machined on bed which is actually the rail and provide the movement to tailstock and carriage.

The anchor and writer. The figure highlights the main parts of a lathe machine. It is a long threaded rod on the bed which provides an automatic feed to carriage from head stock to tail stock. It is used to give different patterns on the fixed length of the work piece. It is done by knurling tool (having two rollers of opposite pattern) touching it to work the piece at low speed. Return to the Mechanical Engineering Department. The spindle, also known as workpiece spindles is used to provide rotational motion to the chuck and then to the workpiece. It is done to make sure that the sharp edges of something dont harm someone who is handling the job. flutes (for added stiffness) and doesn't cut as easily as a drill bit. the bit in. left to right. A cross slide that controls transverse motion of the tool The top of the bed has two longitudinal guideways. The tailstock is a moveable part and could be locked. squeeks, aplly solvent more often. The headstock is fixed on the machine and it consists of many pulleys, lever, spindle, chuck, and gear box. In parting off, we remove a part of a particular length from the remaining job. centre lathe is shown below. Since its used to transfer power, its also called a power screw. Umair has a Bachelors Degree in Electronics and Telecommunication Engineering. material to support the cutting edge during deep cuts. By signing up, you are agreeing to our terms of use. This is an excellent two video series that makes a machinist hammer from scratch. Now the tool can be Angular feed: When the tool moves at an angle to the lathe axis with the help of compound rest. order to make a product / part. The tailstock can also slide on these guideways. positioning, but the saddle doesn't. After drilling, reaming is the process where the hole undergoes correction to a desirable size. (Check out the diagram for a four-way tool post below.). done. be moved by hand.

Chamfering is a safety feature. The gear box is in the head stock which rotates the chuck at different speeds. Due to the relative motion of the job and the cutting tool, the material gets removed from the job in the form of chips and shavings. If the drill bit https://www.britannica.com/technology/speed-lathe. And there are two major components in the carriage. The headstock receives this power from an electric motor, and it uses pullets and gears for obtaining different speeds on the spindle. Updates? The tailstock can move along the bed of the lathe to accommodate different lengths of the work. These may be lathes operated directly by MechCollege is a blog related to mechatronics and mechanical engineering. slide backward as you try to drill). have been programmed to carry out a particular task. Take at most one or two drill diameters of material before backing off, The base of the compound rest is graduated in degrees to indicate its current angular settings. It is used to enlarge the inner diameter of the hole. (click here for video) 983kB, If the part has a very complex geometry, it may be neccesary to install Join our mailing list to get notified about new courses and features, Lathe machine The ultimate guide for beginners. cutting tapers. Read our privacy policy and terms of use. Procedures vary from machine Cross-slide: When the tool moves in a perpendicular direction to the lathe axis. The tailstock can be moved forward or backward by using a screw. A small amount of material is removed in reaming. Job supported by two centers and rotates on its own axis. The tool post is secured to the compound with a T-bolt. Barrel consists of a Dead Centre which is used to support a work piece. It has all the accuracy expected of a precision machine. The process which is used to reduce the length of a work piece is called FACING. It supports the tool post. compound. Depth of cut: It is the depth of penetration of the tool into the workpiece during machining. (click here for video) 860kB. Facing It gives support to all parts of machine like Head stock, Tail stock, Carriage etc. The carriage controls and supports the cutting tool. In a normal bench lathe, there are two spindles. What is the working principle of a Lathe machine? It rotates about its own axis. The bed is the foundation of the lathe machine on which all the other major parts lie. How does an engine/center lathe machine work? Due to the relative motion, the edges of the job undergoes tapering. It is done by giving feed from forward to backward (cross slide movement). Roughing tools have a small side relief angle to leave more So, the feed mechanism consists of all the parts that cause or support this relative motion. The carriage is also a movable part which moves on bed ways. Before starting the machine, turn Check it out. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It is done by using a tool called boring bar along the axis of the work piece.

It moves back and forth to give depth of cut to the metal specimen by using hand wheel. The headstock of a lathe is the side where we fix the workpiece. tailstock into position, and lock the it in place (otherwise it will

Many of

The process in which material is removed from the inside of work piece is called BORING. It consists of a barrel that can move forward and backward. (click here for video) 1.99MB, In order to move the cutting tool, the lathe saddle and cross slide can

The cookie is used to store the user consent for the cookies in the category "Analytics". axis of rotation with the tailstock handwheel. you may use a dial indicator mounted to the saddle. Work is held between two centers and rotates about its own axis. It also provides power for tool movement. In Facing, two centers support the job. This cookie is set by GDPR Cookie Consent plugin. The carriage is a part of the feed mechanism. And its located on the opposite side of the headstock.

It moves back and forth to give depth of cut to the metal specimen by using hand wheel. The headstock of a lathe is the side where we fix the workpiece. tailstock into position, and lock the it in place (otherwise it will

Many of

The process in which material is removed from the inside of work piece is called BORING. It consists of a barrel that can move forward and backward. (click here for video) 1.99MB, In order to move the cutting tool, the lathe saddle and cross slide can

The cookie is used to store the user consent for the cookies in the category "Analytics". axis of rotation with the tailstock handwheel. you may use a dial indicator mounted to the saddle. Work is held between two centers and rotates about its own axis. It also provides power for tool movement. In Facing, two centers support the job. This cookie is set by GDPR Cookie Consent plugin. The carriage is a part of the feed mechanism. And its located on the opposite side of the headstock.  of gears. the collet. The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The dial indicator

My name is Liam Flick. The process which is used to make threads is called THREADING. First, loosen the bolts securing the compound to the saddle. will have a number of alterative gear wheels for this purpose. Retighten the bolts. In this clip, a hole is drilled with a drill bit. They carry the entire load of the machine. Ive learned a lot in the short time it took me to read this. manufactured using lathes. We also use third-party cookies that help us analyze and understand how you use this website.

of gears. the collet. The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The dial indicator

My name is Liam Flick. The process which is used to make threads is called THREADING. First, loosen the bolts securing the compound to the saddle. will have a number of alterative gear wheels for this purpose. Retighten the bolts. In this clip, a hole is drilled with a drill bit. They carry the entire load of the machine. Ive learned a lot in the short time it took me to read this. manufactured using lathes. We also use third-party cookies that help us analyze and understand how you use this website.  The angle of the

Currently, Umair is pursuing his MS in Electronics Engineering from the University of Hertfordshire (Hatfield, UK). And those are as follows. The process which is used to reduce diameter along length gradually is called TAPER TURNING. at the base of the compound. It is permanently fastened at the left end of the lathe on the bed. A handwheel is used for lateral movement. We will dive into each of them and understand their purpose and functions. You should use cutting fluid with the centerdrill. hold the inside diameter of the part. The ratio of longitudinal feed to the speed of headstock spindle should be such that the relative speeds of work and lead screw cause the grooves.

The angle of the

Currently, Umair is pursuing his MS in Electronics Engineering from the University of Hertfordshire (Hatfield, UK). And those are as follows. The process which is used to reduce diameter along length gradually is called TAPER TURNING. at the base of the compound. It is permanently fastened at the left end of the lathe on the bed. A handwheel is used for lateral movement. We will dive into each of them and understand their purpose and functions. You should use cutting fluid with the centerdrill. hold the inside diameter of the part. The ratio of longitudinal feed to the speed of headstock spindle should be such that the relative speeds of work and lead screw cause the grooves. It moves using a feed screw.

(click here for video) 1.07MB Some schools and colleges prefer to train students on the smaller version, due the the costs involved. A pin will press the chuck out of Hope now you know more about Lathe machine parts and understand diagram. However, boring cannot be done prior to drilling. In a lathe machine, the job is held between two centers. These centers support the job and hold it firmly in place. The lead screw is used for screw thread cutting operations. Due to the relative motion between the job and the tool, part of the job gets removed in the form of chips. All rights reserved. Its held at a small angle to the job and moves perpendicular to the job. It is done by using a tool called reamer fixing it on the tail stock like drilling but at low speed. It is done by fixing tool perpendicular to the axis of work piece and by giving automatic feed at low speed. The process which is used to finish already drilled holes in the work piece is called REAMING. The external surface of the front end of the headstock is threaded to provide attachment facilities for job holding devices such as chucks and drives etc. In this post, we will understand a lathe machines working principle, its types, and features, and the operations we can perform on it. Cross slide is on the carriage and moves on the saddle. It is used to make threads of required length and depth on a work piece. You also have the option to opt-out of these cookies. It is done by a tool drill bit fixed it on the tail stock revolving against the revolution of work piece. Feed: It is the distance which the tool moves for each revolution of the work. This is every bit as functional, as a full sized centre lathe, except it is smaller and fits on a bench top. It does not store any personal data. It can be adjusted in position along the ways to This type of lathe is controlled by a Read the privacy policy for more information. Positioning the Tool In this article, you will learn about different parts of the lathe and their functions.

The saddle slides between the headstock and tailstock. The carriage needs power from the operator, so we use the lead screw to transfer power from headstock to carriage. Shoulder turning, eccentric turning, and rough turning are the other three types of turning operations. Knurling operation is done to provide some grip on the job. A lot of the operations that we have seen in this post are shown. The spindle is also movable and can be moved in and out of the barrel. The cross slide is used to move the cutting tool in a perpendicular direction to the axis of the lathe. It is done by giving depth of cut continuously left and right. (click here for video) 2.05MB, The cross slide and compound have a micrometer dial to allow accurate Automatic movement of the carriage is required for constant pitch. However, we cant use the feed rod for thread cutting. Drilling We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. PROCESSES INDEX PAGE. It also used to give finishing the surface of the rod by the diameter of the rod. On an engine lathe the tool is clamped onto a cross slide that is power driven on straight paths parallel or perpendicular to the work axis. These gears are sometimes replaced to alter the speed of Chuck is used for mounting of metal pieces which are not round shape while having a triangular or square shape. The apron is on the front of the saddle which has hand wheel and levers. It carries the cross slide and the toolpost. The legs are made up of cast iron. This website uses cookies to improve your experience while you navigate through the website. The compound rest is mounted on the cross slide. If the diameter reduces uniformly throughout the length of the work, its known as straight turning. rotation of the chuck. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. The cookie is used to store the user consent for the cookies in the category "Performance". Move the is to change the gear arrangement inside the headstock. What are the different types of lathe machines? All Rights Reserved. while the machine is running (a safety feature). You've just moved the saddle forward, so it could : watch turners. smoother feed rate. Always drill past the beginning of the taper to create a funnel to guide presses against a stop (often a micrometer as shown in the clip below). This cookie is set by GDPR Cookie Consent plugin. The bed of the lathe machine is made using cast iron. The bed is the main part of the machine which is fixed. In this operation, the diameter of the work is reduced due to the relative motion between the tool and the job to a desirable dimension. Aluminum is cut best by specially shaped cutting tools (not shown) that (toward or away from the operator). These cookies will be stored in your browser only with your consent. Lets kick things off with a gander at the block diagram of the lathe machine. Return to the machine shop. On a screwcutting lathe. So here we will explain what it is, how to use and their parts. The main parts of a lathe machine are: The carriage of a lathe is a part that provides attachments whose function is to support, guide, and control the cutting tool. The drill chuck can be removed from shapes from a range of materials including; steels and plastics. The tool posts job is to hold the tool in place and to enable us to adjust it to a convenient position. The beam is a base structure of the lathe that supports all the major components of the lathe including the headstock and the tailstock. These are the main parts of the carriage of the lathe: Here are the different operations that can be done on a lathe: Lets understand each of these operations one by one. (click here for video) (2.30MB). The tailstock of a lathe is mounted at the right end of the bed. The process which is used to remove excess material from the work piece is called STEP TURNING. Left hand cutting tools are designed to cut best when traveling from In lathes, the cutting speed is obtained from the rotary motion given to the work. On to the belt sander. It is also used for attachments of tools like drills, tap, etc. typical centre lathe and label the important parts. Always The cookie is used to store the user consent for the cookies in the category "Other. Then Turning Facing tools are ground to provide clearance with a center. No power feed is available for the

The saddle has H shaped. On a speed lathe the cutting tool is supported on a tool rest and manipulated by hand. SOME OF THE EQUIPMENT USED WITH THE CENTRE LATHE. person turning the various handles on the top slide and cross slide in Tailstock provides support to the workpiece along the center of rotation. Chuck is a type of clamp that we use to hold the workpiece in radial symmetry. 2022 - The Encarta - The Digital Encyclopedia. rake to permit cutting in either didection. It has all the functions of the larger version, but has a limited chuck capacity. The left-hand leg houses the electric motor. By clicking Accept, you consent to the use of ALL the cookies. So, each spindle is known as the headstock spindle and toolstock spindle. As a result of that, there are several different chucks used in lathe machines. It moves on left and right.

The job is attached to a chuck. to machine. It is used intaper turning by giving an angle. It is usually expressed in millimeters. It is used for giving threads to the work piece. The job rotates on its own axis. A tool compound that adjusts to permit angular tool movement. It is on the carriage which helps cross slide to move back and forth on the machine. rotate the compound to the desired angle referencing the dial indicator

An apron is attached to the saddle where it hangs. In facing operation, the ends of the work are made flat, and the length of the job is reduced. Analytical cookies are used to understand how visitors interact with the website. What are the different operations that can be done on a lathe machine? The article that we are machining using the lathe machine is known as the job. There is a hand wheel for manual movement of the carriage. What are the three cutting parameters of lathe machines? accomodate different length workpices. The lathe must be switched off before opening,

It is an ideal lathe for precision model makers and for those learning to use a lathe. It is also used to enlarge the drilled hole of the work piece. It is used as mounting and for the position of tool post. It is used to support the job when a chuck is used at the headstock too. They can be secured to the ground using bolts for extra stability. It consists of: The figure above shows a typical cutting tool and the terminology used

go, then about a quarter turn more. Choosing a Cutting Tool

the spindle by hand. However, sometimes the only way to set the lathe to a particular speed

The knurling tool is kept on the toolpost and pressed perpendicularly to the job until the patterns on the rollers are formed on the job. Block diagram of a lathe machine (Engine/Center lathe). The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". interfere with the rotation of the lathe chuck. These patterns are usually square or diamond in shape. use a centerdrill to start the hole. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Whereas in a drilling machine, the job stays still, and the tool rotates. Many people know Lathe machine and saw in there laboratory or company but not aware much about parts of lathe machine and lathe machine diagram . The job needs to be held down securely. This cookie is set by GDPR Cookie Consent plugin. Since the spindle is directly connected to the chuck and the workpiece is directly connected to the chuck, the speed of the workpiece is the same as the spindle speed. It also used to give finishing along the face. Thread cutting is an important operation where helical grooves are produced on the job by feeding the tool longitudinally on the rotating job. It fits on the bed. A handwheel controls the feed screw. Finishing tools have a more rounded nose to provide a finer finish. The parting tool is mounted on the tool post, and the feed is perpendicular to the axis of the job. The tool holder

practicable solution. So, it has the ability to supply power to the workpiece, And its consists of the speed selector, spindle, and chuck. The Centre Lathe is used to manufacture cylindrical

This chuck holds a work piece, so the work pieces also rotate.

The job is attached to a chuck. to machine. It is used intaper turning by giving an angle. It is usually expressed in millimeters. It is used for giving threads to the work piece. The job rotates on its own axis. A tool compound that adjusts to permit angular tool movement. It is on the carriage which helps cross slide to move back and forth on the machine. rotate the compound to the desired angle referencing the dial indicator

An apron is attached to the saddle where it hangs. In facing operation, the ends of the work are made flat, and the length of the job is reduced. Analytical cookies are used to understand how visitors interact with the website. What are the different operations that can be done on a lathe machine? The article that we are machining using the lathe machine is known as the job. There is a hand wheel for manual movement of the carriage. What are the three cutting parameters of lathe machines? accomodate different length workpices. The lathe must be switched off before opening,

It is an ideal lathe for precision model makers and for those learning to use a lathe. It is also used to enlarge the drilled hole of the work piece. It is used as mounting and for the position of tool post. It is used to support the job when a chuck is used at the headstock too. They can be secured to the ground using bolts for extra stability. It consists of: The figure above shows a typical cutting tool and the terminology used

go, then about a quarter turn more. Choosing a Cutting Tool

the spindle by hand. However, sometimes the only way to set the lathe to a particular speed

The knurling tool is kept on the toolpost and pressed perpendicularly to the job until the patterns on the rollers are formed on the job. Block diagram of a lathe machine (Engine/Center lathe). The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". interfere with the rotation of the lathe chuck. These patterns are usually square or diamond in shape. use a centerdrill to start the hole. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Whereas in a drilling machine, the job stays still, and the tool rotates. Many people know Lathe machine and saw in there laboratory or company but not aware much about parts of lathe machine and lathe machine diagram . The job needs to be held down securely. This cookie is set by GDPR Cookie Consent plugin. Since the spindle is directly connected to the chuck and the workpiece is directly connected to the chuck, the speed of the workpiece is the same as the spindle speed. It also used to give finishing along the face. Thread cutting is an important operation where helical grooves are produced on the job by feeding the tool longitudinally on the rotating job. It fits on the bed. A handwheel controls the feed screw. Finishing tools have a more rounded nose to provide a finer finish. The parting tool is mounted on the tool post, and the feed is perpendicular to the axis of the job. The tool holder

practicable solution. So, it has the ability to supply power to the workpiece, And its consists of the speed selector, spindle, and chuck. The Centre Lathe is used to manufacture cylindrical

This chuck holds a work piece, so the work pieces also rotate. Labeled Photograph It consists of the saddle, cross slide, compound rest, top slide or tool post and the apron. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. Let us know if you have suggestions to improve this article (requires login). There are three types of feed of the tool: Longitudinal feed: When the tool moves in parallel to the lathe axis, via a carriage. Necessary cookies are absolutely essential for the website to function properly. So, its used to feed the carriage and the cross slide. The tool moves in parallel to the axis. If a fine finish is required, use both hands to achieve a (click here for video) 554kB, If the part has a very large hole through it, a lathe arbor may not be a Installing a Cutting Tool The legs are the support of the lathe machine. with a center, or to hold tools for drilling, reaming, threading, or Cutting speed: This is the speed at which material is removed by the tool from the workpiece. spindle. Its a fundamental machine in the metal industry and also used in the woodworking industry.

the components that go together to make an engine work have been And the toolstock consists of a few components. the tail stock by drawing back the drill chuck as far as it will easily And it is held slightly inclined to the job though its motion is perpendicular to the axis of the job due to the cross-slide. Learn how your comment data is processed. It's free, informative, and full of knowledge. The tool is fixed on the toolpost. The longitudinal feed should be equal to the pitch of the grooves. The removal of material from metal is called Machining, and the process usually happens in a machine shop that has special equipment. The tool is fixed on the toolpost. These cookies track visitors across websites and collect information to provide customized ads. The spindle is in the head box which rotates a shaft which is connected to the chuck. I share a lot of informational news and knowledge with people. clearing the chips, and applying cutting fluid. The apron contains gears, clutches, and levers for operating the carriage. The compound rest of a lathe is used for obtaining angular cuts, short taperings as well as to position the tool. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Thank you, I was having a hard time finding basics of manual machining. A toolpost T-slot that holds the toolpost. The saddle is an H shaped casting. It is opposite in position to the headstock. Round nose tools are for lighter turning. The cross slide is mounted on the saddle and supports the compound rest. The headstock serves the following purposes: It supports the spindle and provides provisions for a rotating live center. Boring E.g. How are lathe machines classified? The headstock provides the power required for rotating the work at various speeds. To position the saddle accurately, Publisher - The Encarta is the Blog that can help anyone. (click here for video) 1.29MB, Move the saddle forward to make room for the tailstock. Draw a simple diagram of a The cutting tool moves perpendicular to the job. In metal lathe machines, the bed is built using metals and most commonly using cast iron. One belongs to the headstock and the other belongs to the tailstock. Carriage is used to feed and to change the angle of the tool according to the requirements. If the diameter is reduced in an angle, its called taper turning. The process in which diameter of a work piece reduces is called TURNING. The job rotates on its own axis. The drill is fed along the axis of the rotating job, and due to relative motion, we get a hole of a desirable diameter. Our editors will review what youve submitted and determine whether to revise the article. This site uses Akismet to reduce spam. The workpiece is connected to a rotating shaft and a cutting tool is used to remove materials from the rotating workpiece. As the name suggests, the speed selector is used to control the rotating speed of the workpiece. The speed of the lead screws controls the pitch. Advanced Work Holding. Omissions? Its generally expressed in meters/minute. The cutting tool is placed on the tool post. PDF FILE - CLICK HERE FOR A POSTER - THE MODEL ENGINEER CENTRE LATHE, CLICK HERE FOR A POSTER - THE MODEL ENGINEER CENTRE LATHE, CLICK HERE FOR EQUIPMENT AND Lathe Machine All Parts and Functions with Diagrams and Uses, You May Like: Benefits of edu Mail Claim Up To 1000$ Students Discount.

An apron that controls the feed mechanisms. Tool post is on the compound rest and used to clamp the cutting tool. Benefits of edu Mail Claim Up To 1000$ Students Discount, Bubble Sorting in Assembly Language 8086 | Array Sorting, 10 Pieces of Advice for Senior High School Students, How To Get Into An Early Childhood Education Program, Get insights on your website with Contconcord DA Checker, How to Make a Custody Battle Easier on Your Kids, 5 Things Your Lawyer Considers Before Taking Up Your Car. The job rotates about its own axis, but the tool (drill) is fit into the tailstock instead of the toolpost. They have no back or side The cost of one of these lathes is normally much less than a full sized lathe. are used with the cutting edge slightly above center to reduce chatter. If an operation is carried out up to a certain length of the job, its called counter-boring. Parting PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET. And its a shaft that is used to transfer power. In the boring operation, an already drilled hole is enlarged through relative motion between job and tool. It has shallow Its located between the headstock and the tailstock. people (manual lathes) or computer controlled lathes (CNC machines) that Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. Single Point Thread Turning The feed rod is used to transfer power to the carriage just like in the lead screw. The actual geometry varies with the type of work to be Feed, Speed, and Depth of Cut Similarly, the gears, the levers, and the pulleys which transmit motion from the headstock spindle to the carriage are all parts of the feed mechanism of the lathe. The boring tool is fitted to the tool post. (click for computer generated animation of funnel effect, is secured to the tool post using a quick release lever. But opting out of some of these cookies may affect your browsing experience. In the drilling operation that we perform on a lathe machine, the job rotates while the tool stays still. (click here for video) 452kB. You may instead use the outside of the jaws to The cookies is used to store the user consent for the cookies in the category "Necessary". Compound slide is on the cross slide which can rotate.

Next up, we have a similar guide for drilling machines for you. In a drilling operation, a hole is made into the job. It can be done by giving feed from tail stock to head stock and by giving depth of cut. The job is supported by two centers. The bed of a lathe machine is strong enough to resist vibrations due to cutting forces. Moreover, the headstock has rotational motion and also the lead screw. Corrections? hand fed along the desired angle. A saddle that mates with and slides along the ways. although the motor should automatically cut off if the door is opened However, there are different mechanisms to clamp a workpiece in radial symmetry. Here are some of the uses of the tailstock of the lathe: The tailstock is used as a support when the job is turning between the centers. What are the different applications of a lathe machine? The tool that we attach to the lathe machine to perform a particular operation on the job is known as a tool/cutting tool. Lathe machines are probably the most common and important machine in a mechanical tool room. The headstock of a centre lathe can be opened, revealing an arrangement Four-way tool posts can hold four tools at once. When different diameters are obtained over the length, its called step turning. It is used to control the movement ofcarriage on the bed. the part onto a face plate. The relative motion between the tool and the work is known as feed.. The standard cutting tool shapes are shown below. The face plate is then attached to the Change gears are used to engage relative motion between the lead screw and half nut, achieving automatic motion of the carriage. A third axis of motion is provided by the compound. These guideways are made with precision to ensure the accurate alignment of other parts. There are also power feeds for these axes. Note that material is not removed, knurling only creates an impression. It gives support to tool post. There are seven main types of lathe machines that we will be looking at in this course: We are going to completely understand every working principle and every function of the engine/center lathe machine. not yet available). We express it in mm/revolution. The process which is used to give straight lines angled lines and curved lines to a work the piece is called KNURLING. The ram can be fed along the It is mounted on the compound rest and supports the tool. The tailstock can be used to support the end of the workpiece He also holds a Post-Graduate Diploma in Embedded System Design from the Centre of Development of Advanced Computing (Pune, India). This cookie is set by GDPR Cookie Consent plugin. compound can be adjusted to allow tapers to be cut at any desired angle. The compound rest can swivel in any desired angle in the horizontal plane. Description Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. It is done by fixing compound slide on a given angle. These tools or the dead center can be attached at the front of the spindle, which has a tapered hole. In a lathe, depth of cut is the perpendicular distance between the machined and unmachined parts of the work. In modern lathes, pulleys are replaced by gears. Way is machined on bed which is actually the rail and provide the movement to tailstock and carriage.