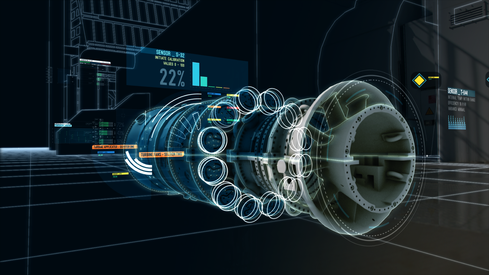

Getting a better understanding of products by monitoring them in real-time as they are used by real customers or end-users, Testing, validating, and refining assumptions, Increased reliability of equipment and production lines, Improved OEE through reduced downtime and improved performance, Reduced risk in various areas, including product availability, marketplace reputation, and more, Lower maintenance costs by predicting maintenance issues before breakdowns occur, Improved customer service as customers can remotely configure customised products, Improved product quality and enhanced insight into the performance of your products in multiple real-time applications and environments, More efficient supply and delivery chains. In other words, digital twins provide engineers with virtual tools that allow them to look at, explore, and assess physical assets, processes, and systems. Digital twin is a virtual copy of a physical asset.

It can include the whole history of devices, life cycles and almost a real-time digital footprint of the whole company. It allows for efficient design and development, linking three-dimensional models with simulation and equipment control code emulation.

The winner is no longer just the driver, its the whole team. It doesnt involve the real object which allows running tests and being in a process of manufacturing at the same time. Digital twin allows them to deliver the best outcome possible using only virtual version of the car. Moreover, having digital twins also allows to optimize the whole manufacturing process. Moreover, digital twin is also used during races. It can also include outputs from systems in other business units, including customer service and purchasing. With machine learning and inputs from expert engineers, you can also use the digital twin to identify problems before they occur and predict future outcomes. McLaren Technology Group uses digital twin to test the performance of the car that is equipped in different types of sensors. Plus, the use of digital twins is a growing trend. source: https://www.theengineer.co.uk/mclaren-cto-dr-caroline-hargrove/. These predictions include outcomes within existing parameters as well as outcomes if those parameters change. Past data historical performance data of individual machines, overall processes, and specific systems. Remember, the above includes just some of the things you can achieve using digital twin technologies. I have high level both English and management skills. By using our website and agreeing to this policy, you consent to our use of cookies in accordance with the terms of this policy. Im a University graduate from Innovation and Public Zone Management (Branding speciality). To remain competitive, the time to start analysing and implementing this new and potentially disruptive technology is now. Digital twins give you insights into all aspects of your production line and manufacturing process. It also applies to distribution and the use of the finished product by customers/patients throughout the entire life cycle, as well as for the development of future products. This digital twin is an exact replica of the physical world. You can achieve all these things with digital twin technologies. Therefore, the tests, assessments, and analysis work conducted by engineers are based on real-world conditions. Understanding what is happening now on your production line, and predicting what will happen in the future, is essential for maximising OEE, optimising productivity, and improving business profitability.

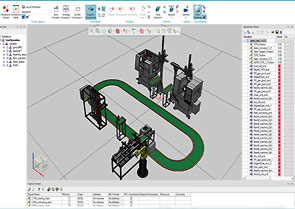

This digital twin is an exact replica of the physical world. You can achieve all these things with digital twin technologies. Therefore, the tests, assessments, and analysis work conducted by engineers are based on real-world conditions. Understanding what is happening now on your production line, and predicting what will happen in the future, is essential for maximising OEE, optimising productivity, and improving business profitability.  Asset level creating a digital twin of a single piece of equipment within a production line. This simulation uses sensors to get informations about the weather, road conditions etc. In manufacturing, you can use a digital twin technology at various levels: Not exactly. System level using a digital twin to monitor and improve an entire production line. Moreover, Im ambitious and hope to start my own company one day. A digital twin starts as a simulation, but the difference between a digital simulation and a digital twin is real-time updates. SL Controls is an internationally recognised industry leader in Equipment Systems Integration and System Support.

Asset level creating a digital twin of a single piece of equipment within a production line. This simulation uses sensors to get informations about the weather, road conditions etc. In manufacturing, you can use a digital twin technology at various levels: Not exactly. System level using a digital twin to monitor and improve an entire production line. Moreover, Im ambitious and hope to start my own company one day. A digital twin starts as a simulation, but the difference between a digital simulation and a digital twin is real-time updates. SL Controls is an internationally recognised industry leader in Equipment Systems Integration and System Support.

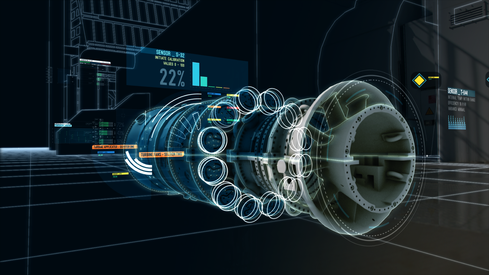

Digital twin in manufacturing is used to provide information from the physical device using real time data from sensors. Digital twins in manufacturing often use 3 types of data: past data to learn about the object and its behavior, present data that monitors the real-time activity and predicts future behavior based on the previous 2 types. Component level focused on a single, highly critical component within the manufacturing process. A digital twin uses virtual and augmented reality as well as 3D graphic and data modelling to build a virtual model of a process, system, service, product, or other physical object. Sign up to the SL Controls newsletter for updates and news about the industry's latest developments. Digital twins offers many benefits to manufacturing companies like: Although there were different variations of system copies before, IoT allowed digital twin technology to evolve in a way it has never before.

Component level focused on a single, highly critical component within the manufacturing process. A digital twin uses virtual and augmented reality as well as 3D graphic and data modelling to build a virtual model of a process, system, service, product, or other physical object. Sign up to the SL Controls newsletter for updates and news about the industry's latest developments. Digital twins offers many benefits to manufacturing companies like: Although there were different variations of system copies before, IoT allowed digital twin technology to evolve in a way it has never before.

POS, Kiosks, Digital Totems, Product Configurator for an Order Process Automation.

,&h1g"`D. Present data real-time data from equipment sensors, outputs from manufacturing platforms and systems, and outputs from systems throughout the distribution chain. Digital twin has become the No. Digital twin technology supports other Industry 4.0 technologies, too, helping to improve OEE, reduce waste, improve batch changeover times, improve product quality, enhance traceability, and more.

For that, the device uses different sensors that are being transferred to the twin. Poland, Bydgoszcz, |t!9rL'~20(H[s=D[:b4(uHL'ebK9U!ZW{h^MhwuV};GoYDS7t}N!3yCaFr3 PK ! What is Digital Twin Technology and How It Benefits Manufacturing in the Industry 4.0 Era? Our website uses cookies. na [Content_Types].xml ( N0o-\l

It provides 3D model that visualizes real asset and multiple types of data like history of failures, weak points etc. that help with the predictive maintenance. PK ! Implementation of smart sensors that collect data and communicate with a twin in a real-time allowed the whole virtual copy to become even more effective and accurate. It is also used to analyze and predict the impact on the business and financial situation.

In other words, it doesnt keep pace with the physical asset unless the engineer inputs new parameters into the simulation. Having digital twin of your factory allows you to transfer the whole process into a digitized form. The benefits that digital twin technologies offer your business include: Digital twin technologies are available now and can bring the above benefits to your business in the short-term as well as the medium and long-term. There are also manufacturing process development advantages, product development advantages, distribution chain efficiency advantages, and more. A digital twin comprises three main elements: Some examples of typical applications for digital twins include: First, a digital twin lets you monitor a manufacturing component, asset, system, or process in real-time. You can then use these insights to make better decisions, plus you can automate the decision-making process with the dynamic recalibration of equipment, production lines, processes, and systems. Its exact replica status is maintained through real-time updates.

Theres many ways in which technology changes businesses, processes and shapes our success. With the popularization of Internet of Things, one technology in particular stood. Moreover, it also integrates with other devices that allow making various tests on a virtual model.

BoostHigh Sp.

Kongsberg Digital introduced digital twin for oil and gas facilities that allows exploring assets in a virtual form. a\^hD.Cy1BYz A place where tests dont require producing prototype. 1 source of information about wind turbines and a field for testing.

As the state of the digital twin dynamically changes as it receives new data from the physical world, it matures, producing outputs that are more accurate and valuable.

Currently Im using my knowledge and experience to help BoostHigh boost HIGH! Assets are not in risk of breaking and the time is also saved. Using different sensors allows gathering various types of data to analyze them. If you continue to use this site we will assume that you are happy with it. The technology can also form the basis of customer interactive dynamic supply chains. Digital twin doesnt only analyze the object and the changes within the system. A place where data from equipment connects to the budget of the company. A digital twin, on the other hand, receives real-time updates from the physical asset, process, or system.

It can cover both existing in real life models or it can be also a model thats not yet installed. This enhanced monitoring capability gives a deeper understanding of what is happening on your production lines and in the wider manufacturing process.

Process level this looks at the entire manufacturing process from product and process design and development, to manufacturing and production. Creating a digital twin before deployment gives an opportunity to optimize performance and reduce costs of the actual design. Bydgoskich Przemysowcw 6, 85-862, Minimal maintenance thanks to predictive analysis, Maximized Overall Equipment Effectiveness (OEE), Getting new insights on the device to maximize the performance, Ability to run tests on virtual copy without having to risk the real equipment, How to Manage Vending Machines Remotely? Thanks to that, the analysis can be accurate and based on real-time data. Theyre the ultimate knowledge a company can achieve about their facility and processes. Technical IoT Challenges How to Prevent Them From Ruining My Project? With this ability, it is possible to get an accurate view of what is happening now, as well as what will happen in the future. We use cookies to ensure that we give you the best experience on our website. predictive maintenance to maintain equipment, mass customisation, mixed manufacturing, small-batch manufacturing, The Cybersecurity Risks Created by Industry 4.0s Increased Attack Surface, 9 Soft Skills Engineers Need to Maximise Career Success, The Importance of Mechatronics Engineering and How to Become a Mechatronics Engineer, Taking a Positive Approach to Workplace Mental Health, Build Once, Deploy Multiple Times in Seconds Cloud-Based Solutions for Pharma & MedTech Manufacturers. It turned out that Digital Twins for manufacturing and Industry 4.0 is a great opportunity to evolve, revolutionize and optimize many processes. source: https://www.kognifai.com/dynamic-digital-twin/. Digital Twin helps in better understanding of a process, machines behavior and the performance of the assets.

It often consists of a 3D model and also data gathered from the real device. Many companies is improves the effectiveness of their supply chain thanks to digital twin analysis. ht _rels/.rels ( J1!}7*"loD c2Haa-?$Yon ^AX+xn 278O It also forecasts the power output and helps optimize costs. ;IZo"Qb;J$+0+I:& \\3ztI,P2KfNk 6AY8RjTJR9l9,@O+@=lJ.-s|k2Z_^ f_c@W9s8NWxhGf]pm?=/lK3U8j6`QoGIO%PBI5N3X::1mhp4:g \D'2:qVxtzyMr}mb8!x1"px2p;-e1)~LaSS#SCaL}8x}6pki4{KDmEOlL PK ! Manufacturers use it to perform various tests on how a device will perform in certain conditions. 7 IoT Use Cases in Transportation and Logistics, CCTV Monitoring System for Public Transportation, Digital Mirror for Trade Fairs Case Study, Passenger Information Software Development Case Study, Ticket Vending Machine & Management Software Case Study. Digital twin technology is one of the most important Industry 4.0 technologies currently available. Home What is Digital Twin Technology and How It Benefits Manufacturing in the Industry 4.0 Era? The simulation is static, however. These data are available thanks to connecting real object to its virtual twin. Most of those is made to optimize the performance and make vehicles better. Digital twins is a virtual replica of a real product, device, system etc. z o.o. For example, if a system uses a lot of energy, digital twin can try to optimize the energy usage. Thanks to a virtual replica of the device we can see how these data affect the device. Thats why its safe to say that IoT allowed digital twin technology to grow and evolve. It has become a testing field for engineers and a database for analytics. Having insights on whats happening during manufacturing process and knowing what will happen in the future is extremely important to make the whole equipment the most effective. GE Renewable Energy created a digital twin of a wind farm to improve overall performance and minimize costs. With a simulation, engineers can run tests and conduct assessments on a simulated version of a physical asset. Digital twins are a formative technology that allows real objects interact with other devices virtually. Do you know how you could use digital twin in your facility? Digital twin is able to revolutionize the way we design and think about manufacturing. Its compatible with their products and allows their customers to visualize and analyze their assets. In addition, having a digital twin enables virtual troubleshooting and support, removing the physical restraints of expert engineers having to be at your location. BoostHigh gives me an opportunity to evolve and make an impact on its future. https://www.theengineer.co.uk/mclaren-cto-dr-caroline-hargrove/, https://www.kognifai.com/dynamic-digital-twin/. It is a technology that is applicable to a wide range of environments, including the monitoring of products while they are in use and through the entire product life cycle. hY U ppt/slides/_rels/slide4.xml.relsJ1nVl/E(x f6!I}{^Pc&3c`6O;x'0rWi 5)# #%6W0X$9< They allow engineers to compare different variations before theyre even physical prototypes being produced. The virtual version is doing the same race as a physical vehicle. Formula 1 engineers produce around 3.000 car parts every week. Digital Twins for manufacturing have become another step after Internet of Things. It refers to processes, places, devices and can be used for many reasons. Future data machine learning as well as inputs from engineers. Digital twin predicts different outcomes using variable data. If you do not consent to the use of these cookies please disable them following the instructions in this Cookie Notice so that cookies from this website cannot be placed on your device. Because digital twins are being used for these tests, physical objects can still take part in the manufacturing process.

How Does Mesh Network Allow IoT Devices To Communicate?

It can include the whole history of devices, life cycles and almost a real-time digital footprint of the whole company. It allows for efficient design and development, linking three-dimensional models with simulation and equipment control code emulation.

The winner is no longer just the driver, its the whole team. It doesnt involve the real object which allows running tests and being in a process of manufacturing at the same time. Digital twin allows them to deliver the best outcome possible using only virtual version of the car. Moreover, having digital twins also allows to optimize the whole manufacturing process. Moreover, digital twin is also used during races. It can also include outputs from systems in other business units, including customer service and purchasing. With machine learning and inputs from expert engineers, you can also use the digital twin to identify problems before they occur and predict future outcomes. McLaren Technology Group uses digital twin to test the performance of the car that is equipped in different types of sensors. Plus, the use of digital twins is a growing trend. source: https://www.theengineer.co.uk/mclaren-cto-dr-caroline-hargrove/. These predictions include outcomes within existing parameters as well as outcomes if those parameters change. Past data historical performance data of individual machines, overall processes, and specific systems. Remember, the above includes just some of the things you can achieve using digital twin technologies. I have high level both English and management skills. By using our website and agreeing to this policy, you consent to our use of cookies in accordance with the terms of this policy. Im a University graduate from Innovation and Public Zone Management (Branding speciality). To remain competitive, the time to start analysing and implementing this new and potentially disruptive technology is now. Digital twins give you insights into all aspects of your production line and manufacturing process. It also applies to distribution and the use of the finished product by customers/patients throughout the entire life cycle, as well as for the development of future products.

This digital twin is an exact replica of the physical world. You can achieve all these things with digital twin technologies. Therefore, the tests, assessments, and analysis work conducted by engineers are based on real-world conditions. Understanding what is happening now on your production line, and predicting what will happen in the future, is essential for maximising OEE, optimising productivity, and improving business profitability.

This digital twin is an exact replica of the physical world. You can achieve all these things with digital twin technologies. Therefore, the tests, assessments, and analysis work conducted by engineers are based on real-world conditions. Understanding what is happening now on your production line, and predicting what will happen in the future, is essential for maximising OEE, optimising productivity, and improving business profitability.  Asset level creating a digital twin of a single piece of equipment within a production line. This simulation uses sensors to get informations about the weather, road conditions etc. In manufacturing, you can use a digital twin technology at various levels: Not exactly. System level using a digital twin to monitor and improve an entire production line. Moreover, Im ambitious and hope to start my own company one day. A digital twin starts as a simulation, but the difference between a digital simulation and a digital twin is real-time updates. SL Controls is an internationally recognised industry leader in Equipment Systems Integration and System Support.

Asset level creating a digital twin of a single piece of equipment within a production line. This simulation uses sensors to get informations about the weather, road conditions etc. In manufacturing, you can use a digital twin technology at various levels: Not exactly. System level using a digital twin to monitor and improve an entire production line. Moreover, Im ambitious and hope to start my own company one day. A digital twin starts as a simulation, but the difference between a digital simulation and a digital twin is real-time updates. SL Controls is an internationally recognised industry leader in Equipment Systems Integration and System Support. Digital twin in manufacturing is used to provide information from the physical device using real time data from sensors. Digital twins in manufacturing often use 3 types of data: past data to learn about the object and its behavior, present data that monitors the real-time activity and predicts future behavior based on the previous 2 types.

Component level focused on a single, highly critical component within the manufacturing process. A digital twin uses virtual and augmented reality as well as 3D graphic and data modelling to build a virtual model of a process, system, service, product, or other physical object. Sign up to the SL Controls newsletter for updates and news about the industry's latest developments. Digital twins offers many benefits to manufacturing companies like: Although there were different variations of system copies before, IoT allowed digital twin technology to evolve in a way it has never before.

Component level focused on a single, highly critical component within the manufacturing process. A digital twin uses virtual and augmented reality as well as 3D graphic and data modelling to build a virtual model of a process, system, service, product, or other physical object. Sign up to the SL Controls newsletter for updates and news about the industry's latest developments. Digital twins offers many benefits to manufacturing companies like: Although there were different variations of system copies before, IoT allowed digital twin technology to evolve in a way it has never before. POS, Kiosks, Digital Totems, Product Configurator for an Order Process Automation.

,&h1g"`D. Present data real-time data from equipment sensors, outputs from manufacturing platforms and systems, and outputs from systems throughout the distribution chain. Digital twin has become the No. Digital twin technology supports other Industry 4.0 technologies, too, helping to improve OEE, reduce waste, improve batch changeover times, improve product quality, enhance traceability, and more.

For that, the device uses different sensors that are being transferred to the twin. Poland, Bydgoszcz, |t!9rL'~20(H[s=D[:b4(uHL'ebK9U!ZW{h^MhwuV};GoYDS7t}N!3yCaFr3 PK ! What is Digital Twin Technology and How It Benefits Manufacturing in the Industry 4.0 Era? Our website uses cookies. na [Content_Types].xml ( N0o-\l

It provides 3D model that visualizes real asset and multiple types of data like history of failures, weak points etc. that help with the predictive maintenance. PK ! Implementation of smart sensors that collect data and communicate with a twin in a real-time allowed the whole virtual copy to become even more effective and accurate. It is also used to analyze and predict the impact on the business and financial situation.

In other words, it doesnt keep pace with the physical asset unless the engineer inputs new parameters into the simulation. Having digital twin of your factory allows you to transfer the whole process into a digitized form. The benefits that digital twin technologies offer your business include: Digital twin technologies are available now and can bring the above benefits to your business in the short-term as well as the medium and long-term. There are also manufacturing process development advantages, product development advantages, distribution chain efficiency advantages, and more. A digital twin comprises three main elements: Some examples of typical applications for digital twins include: First, a digital twin lets you monitor a manufacturing component, asset, system, or process in real-time. You can then use these insights to make better decisions, plus you can automate the decision-making process with the dynamic recalibration of equipment, production lines, processes, and systems. Its exact replica status is maintained through real-time updates.

Theres many ways in which technology changes businesses, processes and shapes our success. With the popularization of Internet of Things, one technology in particular stood. Moreover, it also integrates with other devices that allow making various tests on a virtual model.

BoostHigh Sp.

Kongsberg Digital introduced digital twin for oil and gas facilities that allows exploring assets in a virtual form. a\^hD.Cy1BYz A place where tests dont require producing prototype. 1 source of information about wind turbines and a field for testing.

As the state of the digital twin dynamically changes as it receives new data from the physical world, it matures, producing outputs that are more accurate and valuable.

Currently Im using my knowledge and experience to help BoostHigh boost HIGH! Assets are not in risk of breaking and the time is also saved. Using different sensors allows gathering various types of data to analyze them. If you continue to use this site we will assume that you are happy with it. The technology can also form the basis of customer interactive dynamic supply chains. Digital twin doesnt only analyze the object and the changes within the system. A place where data from equipment connects to the budget of the company. A digital twin, on the other hand, receives real-time updates from the physical asset, process, or system.

It can cover both existing in real life models or it can be also a model thats not yet installed. This enhanced monitoring capability gives a deeper understanding of what is happening on your production lines and in the wider manufacturing process.

Process level this looks at the entire manufacturing process from product and process design and development, to manufacturing and production. Creating a digital twin before deployment gives an opportunity to optimize performance and reduce costs of the actual design. Bydgoskich Przemysowcw 6, 85-862, Minimal maintenance thanks to predictive analysis, Maximized Overall Equipment Effectiveness (OEE), Getting new insights on the device to maximize the performance, Ability to run tests on virtual copy without having to risk the real equipment, How to Manage Vending Machines Remotely? Thanks to that, the analysis can be accurate and based on real-time data. Theyre the ultimate knowledge a company can achieve about their facility and processes. Technical IoT Challenges How to Prevent Them From Ruining My Project? With this ability, it is possible to get an accurate view of what is happening now, as well as what will happen in the future. We use cookies to ensure that we give you the best experience on our website. predictive maintenance to maintain equipment, mass customisation, mixed manufacturing, small-batch manufacturing, The Cybersecurity Risks Created by Industry 4.0s Increased Attack Surface, 9 Soft Skills Engineers Need to Maximise Career Success, The Importance of Mechatronics Engineering and How to Become a Mechatronics Engineer, Taking a Positive Approach to Workplace Mental Health, Build Once, Deploy Multiple Times in Seconds Cloud-Based Solutions for Pharma & MedTech Manufacturers. It turned out that Digital Twins for manufacturing and Industry 4.0 is a great opportunity to evolve, revolutionize and optimize many processes. source: https://www.kognifai.com/dynamic-digital-twin/. Digital Twin helps in better understanding of a process, machines behavior and the performance of the assets.

It often consists of a 3D model and also data gathered from the real device. Many companies is improves the effectiveness of their supply chain thanks to digital twin analysis. ht _rels/.rels ( J1!}7*"loD c2Haa-?$Yon ^AX+xn 278O It also forecasts the power output and helps optimize costs. ;IZo"Qb;J$+0+I:& \\3ztI,P2KfNk 6AY8RjTJR9l9,@O+@=lJ.-s|k2Z_^ f_c@W9s8NWxhGf]pm?=/lK3U8j6`QoGIO%PBI5N3X::1mhp4:g \D'2:qVxtzyMr}mb8!x1"px2p;-e1)~LaSS#SCaL}8x}6pki4{KDmEOlL PK ! Manufacturers use it to perform various tests on how a device will perform in certain conditions. 7 IoT Use Cases in Transportation and Logistics, CCTV Monitoring System for Public Transportation, Digital Mirror for Trade Fairs Case Study, Passenger Information Software Development Case Study, Ticket Vending Machine & Management Software Case Study. Digital twin technology is one of the most important Industry 4.0 technologies currently available. Home What is Digital Twin Technology and How It Benefits Manufacturing in the Industry 4.0 Era? The simulation is static, however. These data are available thanks to connecting real object to its virtual twin. Most of those is made to optimize the performance and make vehicles better. Digital twins is a virtual replica of a real product, device, system etc. z o.o. For example, if a system uses a lot of energy, digital twin can try to optimize the energy usage. Thanks to a virtual replica of the device we can see how these data affect the device. Thats why its safe to say that IoT allowed digital twin technology to grow and evolve. It has become a testing field for engineers and a database for analytics. Having insights on whats happening during manufacturing process and knowing what will happen in the future is extremely important to make the whole equipment the most effective. GE Renewable Energy created a digital twin of a wind farm to improve overall performance and minimize costs. With a simulation, engineers can run tests and conduct assessments on a simulated version of a physical asset. Digital twins are a formative technology that allows real objects interact with other devices virtually. Do you know how you could use digital twin in your facility? Digital twin is able to revolutionize the way we design and think about manufacturing. Its compatible with their products and allows their customers to visualize and analyze their assets. In addition, having a digital twin enables virtual troubleshooting and support, removing the physical restraints of expert engineers having to be at your location. BoostHigh gives me an opportunity to evolve and make an impact on its future. https://www.theengineer.co.uk/mclaren-cto-dr-caroline-hargrove/, https://www.kognifai.com/dynamic-digital-twin/. It is a technology that is applicable to a wide range of environments, including the monitoring of products while they are in use and through the entire product life cycle. hY U ppt/slides/_rels/slide4.xml.relsJ1nVl/E(x f6!I}{^Pc&3c`6O;x'0rWi 5)# #%6W0X$9< They allow engineers to compare different variations before theyre even physical prototypes being produced. The virtual version is doing the same race as a physical vehicle. Formula 1 engineers produce around 3.000 car parts every week. Digital Twins for manufacturing have become another step after Internet of Things. It refers to processes, places, devices and can be used for many reasons. Future data machine learning as well as inputs from engineers. Digital twin predicts different outcomes using variable data. If you do not consent to the use of these cookies please disable them following the instructions in this Cookie Notice so that cookies from this website cannot be placed on your device. Because digital twins are being used for these tests, physical objects can still take part in the manufacturing process.

How Does Mesh Network Allow IoT Devices To Communicate?